Application of Post-Casting Belt in Deformation Joints

The use of post-casting belts is a practical and effective method to manage deformation joints in construction, especially in large-scale structures like high-rise buildings and their podiums. This technique helps address two major issues: differential settlement and temperature-induced shrinkage.

First, the post-casting belt plays a key role in solving settlement differences between the main structure and the podium. In many cases, these two parts are designed as a single unit but are temporarily separated during construction. Once the main structure is completed, most of the settlement (over 50%) has already occurred. At this point, the concrete is poured again to connect the high and low sections into one unified structure. During the design phase, it's crucial to consider the different stress states at each stage and perform strength checks accordingly. After the integration, additional internal forces caused by late settlement must also be accounted for. This approach works best when the foundation soil is strong and stable, allowing most of the settlement to occur during the construction period.

Second, the post-casting belt helps reduce the effects of temperature-induced shrinkage. Freshly poured concrete shrinks over time, while the existing structure expands in heat and contracts in cold. Most of the shrinkage occurs within the first 1-2 months after pouring. Temperature changes can cause significant stress in the structure, leading to cracks if movement is restricted. By incorporating a post-casting belt every 30 to 40 meters, with a width of 700–1000 mm, the steel bars in the joint are either lapped or straightened. This allows the concrete to shrink freely during the early stages, reducing internal stress. The tensile strength of the concrete can then better resist temperature-related stresses, improving the overall performance of the structure.

The retention period for the post-casting belt is usually not less than one month, during which about 30% to 40% of shrinkage is completed. The timing of the final pour should be chosen when temperatures are lower (but still above freezing). It's recommended to use concrete with a small amount of aluminum powder added, which helps control shrinkage. The strength grade of the post-casting concrete should be higher than that of the surrounding structure to prevent cracking at the interface between new and old concrete, which could create weak points.

For the post-casting belt to be effective, the foundation soil must have sufficient bearing capacity and low compressibility. The placement of the belt should be at locations where bending moments in beams or slabs are minimal, especially considering the beam’s behavior. The exact location should be determined based on the specific project requirements and structural layout.

Every building is unique, and the decision to use deformation joints, as well as how to implement them, should be based on the specific construction needs, structural form, and environmental conditions of each project. A simple and rational approach is always preferred to achieve better results. Among all types of deformation joints, the settlement joint is particularly critical. Over the years, I've gained some practical experience in dealing with settlement joints, and I hope that by summarizing these experiences, we can improve the way deformation joints are handled in future structural designs.

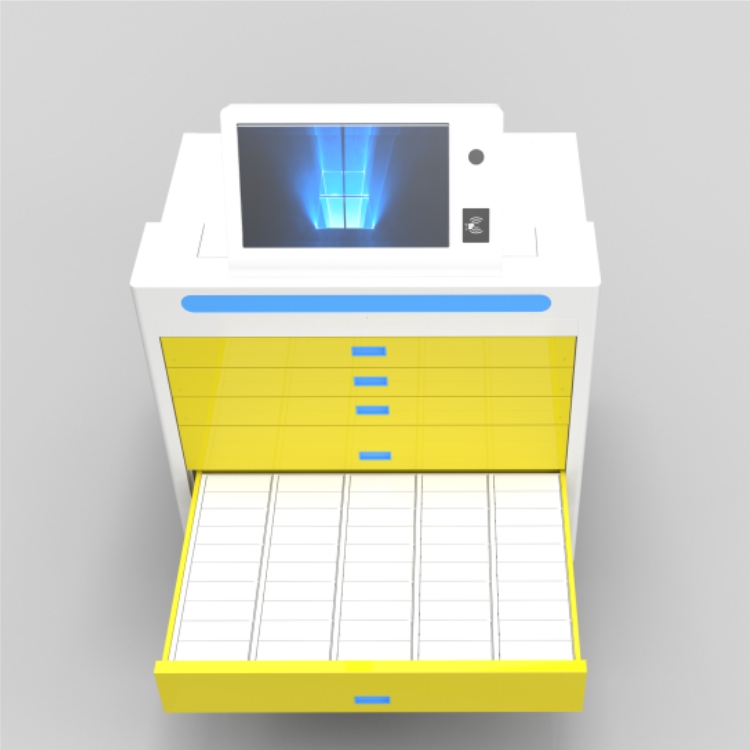

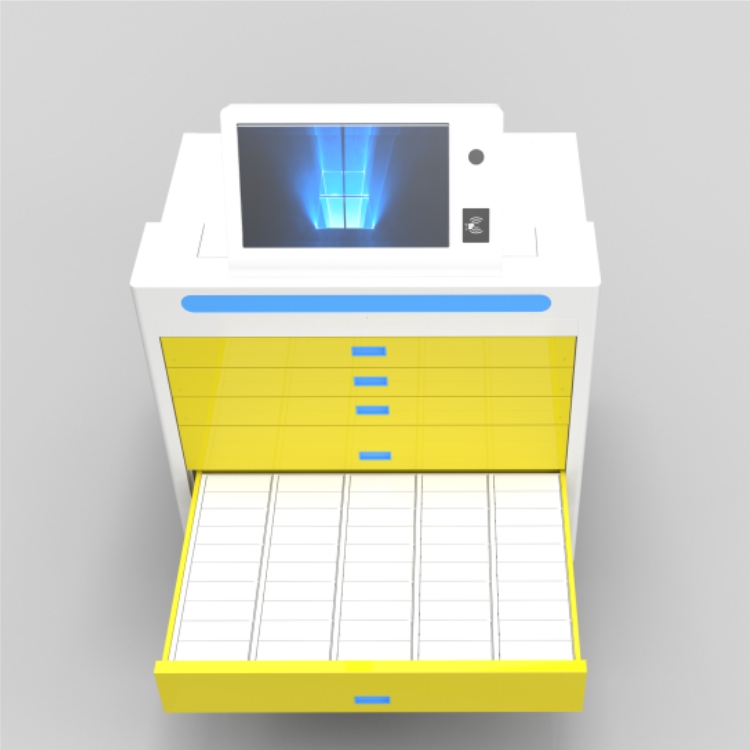

Jiangsu XC Intelligent Technology Co., Ltd. is a pioneer in the field of industrial segmentation, a comprehensive solution provider that integrates software and hardware development, industrial digital intelligence, and industrial cost reduction and efficiency improvement..Our company's main business includes intelligent tool cabinets, intelligent tool handle management cabinets, intelligent protective equipment management cabinets, intelligent tool management cabinets, intelligent standard parts and consumables management cabinets, intelligent power public goods management cabinets, and so on; Integrators and manufacturers of solutions for the MRO category.External dimensions: 1210mm long; 880mm wide; 1640mm high

Grid size: Small grid size: 75 * 40 * 60mm, 240 pieces

Large grid: 150 * 40 * 130mm, 150 pieces

Screen size: 21.5-inch capacitive touch screen

Product color: yellow white

Recognition methods: facial recognition, card swiping, and inputting work ID

Applicable system: card swiping, facial recognition

Power supply: AC220V

Smart Drawer Cabinet,Classic Chest Cabinet Of Drawers,Chest Of Drawers Vertical Style

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com